定制雷射系統

- 旋轉台雷射打標機

- Inline PCB Laser Marker

- Precision Laser Welding

- TFT Gantry Dual Laser Marker

- Touch Panel Laser Marker

- Sapphire Wafer Laser Marker

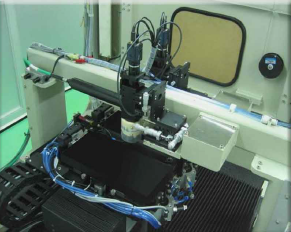

Rotary Table Laser Marker

A stand alone semi-auto machine with small footprint, this system is the ideal choice when space is a concern. Equipped with 2 marking stations, marking and loading can be done simultaneously and thus laser processing time can be greatly reduced. Integration can be done with any of our lasers and additional theta stage can also be added for marking on curve surfaces.

Advantages of a Rotary Table

- Faster cycle time - Laser marking and loading & unloading done concurrently

- Class ONE safety enclosure - Laser beam fully enclosed within marking compartment

- Possible to configured from 2 to 6 stations

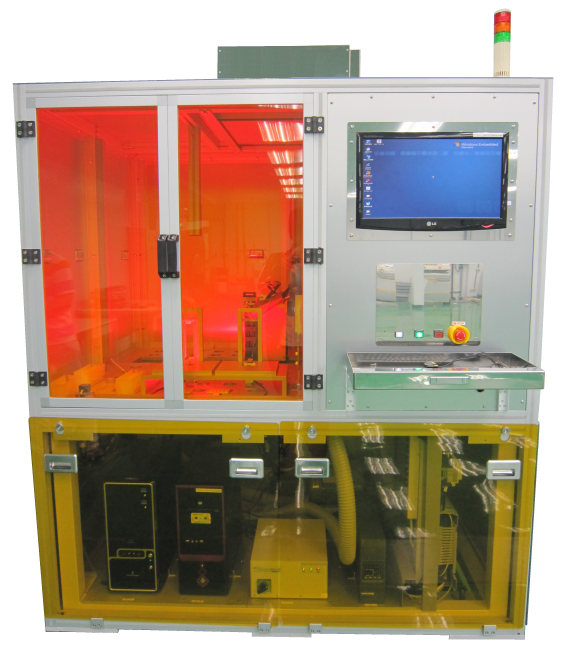

In-line PCB Laser Marker

In Laser Marking, a laser beam is used to make permanent marks on materials such as glass, various types of plastics and polymers, gold, sliver, stainless steel, aluminum, anodized aluminum, copper, brass, other metal alloys, ceramic etc.

The marking content includes texts, logos, different shapes, graphics, patterns, barcodes and 2D matrixes. Some areas that will affect the marking result include the type of laser used, the parameter settings as well as the material itself.

We deliver practical solutions that our customers required to succeed in a world in action with an establish product range of Lasers and Vision Systems.

Advantages of Inline PCB Marker

- In-line handler

- Vision positioning

- Marking inspection

- Adjustable conveyer for various models

- Multi-position and orientation marking

- User friendly sofware under XP system

High Precision Laser Welder

Laser welding uses a laser beam to joint usually two materials together, usually without any additional materials, by using the heat generated by the focused laser beam to melt the materials together.

Hylax specializes in high precision, high speed micro-welding applications on stainless steel components and welding of plastic polymers, including welding of transparent plastic materials.

High Speed Fixed Optics Option

- Ultra High Speed Linear Motor Motion

- Mirco-spot Welding

- High Precision Linear Motor XY Stage with +/- 1 micron position repeatability

- Repeatable spot diameter with auto power feedback control

- User friendly CAD base weld positions settings program

Ultra High Speed ScanHead (ScanVision™) Option

- High UPH - 4x faster compare to fixed optics laser welding system

- Micron level accuracy scanhead welding system

- Rapid precision mirco welding is required in many micro precision engineering parts, for example, HDD head gimbal assembly (HGA)

- ScanVision™ was later implemented which greatly improve the UPH

TFT Gantry Dual Laser Marker

For manufacturing efficiency, flat display panels are manufactured in a big glass panel form. The glass is later cut into smaller, actual usable panels for use in LCD TV, mobile phone display, PDA etc.

Material tracking data markings are needed on specific location of the Flat Panel Display with chrome coating on it. This is done mainly at the beginning of the manufacturing process, on a big piece of uncut TFT glass panel. Those data marks are marked onto every individual subpanel. In most cases, marking specs allows a maximum of 15 um positioning tolerance. ScanVisionTM solution is very beneficial to this system. An XY gantry transports the dual ScanVisionTM lasers to mark the subpanels section by section. With the built-in, high accuracy vision compensation, all marks on the subpanels can be done within the required tolerance, without needing a highly precise mechanical positioning system. As the marking is using 2D codes, the image each mark is then captured by the same camera and decoded for a good mark.

The biggest panel size machine incorporating this technology is a Generation 6 (G6) panel of size 1500mm x 1850mm. These panels are transported by high speed conveyor system where the stopping position can deviate in the range of millimeters. However as long as the fiducial mark is within the camera field of view this is not a problem. Furthermore even if it falls outside sometimes, a rapid searching pattern can be done to find the fiducial since the galvo mirrors can move so fast. As a fiducial registration is done just before every mark and the time between the 2 can be below 100 ms the chances of the workpiece drifting during that interval is quite negligible.

Advantages of TFT Gantry Dual Marker

- Inline handler

- Vision positioning

- Marking inspection

- Adjustable conveyor for various models

- Multi-position and orientation marking

- User friendly software under Windows XP

Touch Panel Laser Marker

For manufacturing efficiency, flat display panels are manufactured in a big glass panel form. The glass is later cut into smaller, actual usable panels for use in LCD TV, mobile phone display, PDA etc.

Material tracking data markings are needed on specific location of the Flat Panel Display with chrome coating on it. This is done mainly at the beginning of the manufacturing process, on a big piece of uncut TFT glass panel. Those data marks are marked onto every individual subpanel. In most cases, marking specs allows a maximum of 15 um positioning tolerance. ScanVisionTM solution is very beneficial to this system. An XY gantry transports the dual ScanVisionTM lasers to mark the subpanels section by section. With the built-in, high accuracy vision compensation, all marks on the subpanels can be done within the required tolerance, without needing a highly precise mechanical positioning system. As the marking is using 2D codes, the image each mark is then captured by the same camera and decoded for a good mark.

The biggest panel size machine incorporating this technology is a Generation 6 (G6) panel of size 1500mm x 1850mm. These panels are transported by high speed conveyor system where the stopping position can deviate in the range of millimeters. However as long as the fiducial mark is within the camera field of view this is not a problem. Furthermore even if it falls outside sometimes, a rapid searching pattern can be done to find the fiducial since the galvo mirrors can move so fast. As a fiducial registration is done just before every mark and the time between the 2 can be below 100 ms the chances of the workpiece drifting during that interval is quite negligible.

Marker in actionAdvantages of TFT Gantry Dual Marker

- Inline handler

- Vision positioning

- Marking inspection

- Adjustable conveyor for various models

- Multi-position and orientation marking

- User friendly software under Windows XP

Sapphire Wafer Laser Marker

For manufacturing efficiency, flat display panels are manufactured in a big glass panel form. The glass is later cut into smaller, actual usable panels for use in LCD TV, mobile phone display, PDA etc.

Material tracking data markings are needed on specific location of the Flat Panel Display with chrome coating on it. This is done mainly at the beginning of the manufacturing process, on a big piece of uncut TFT glass panel. Those data marks are marked onto every individual subpanel. In most cases, marking specs allows a maximum of 15 um positioning tolerance. ScanVisionTM solution is very beneficial to this system. An XY gantry transports the dual ScanVisionTM lasers to mark the subpanels section by section. With the built-in, high accuracy vision compensation, all marks on the subpanels can be done within the required tolerance, without needing a highly precise mechanical positioning system. As the marking is using 2D codes, the image each mark is then captured by the same camera and decoded for a good mark.

The biggest panel size machine incorporating this technology is a Generation 6 (G6) panel of size 1500mm x 1850mm. These panels are transported by high speed conveyor system where the stopping position can deviate in the range of millimeters. However as long as the fiducial mark is within the camera field of view this is not a problem. Furthermore even if it falls outside sometimes, a rapid searching pattern can be done to find the fiducial since the galvo mirrors can move so fast. As a fiducial registration is done just before every mark and the time between the 2 can be below 100 ms the chances of the workpiece drifting during that interval is quite negligible.

Marker in actionAdvantages of TFT Gantry Dual Marker

- Inline handler

- Vision positioning

- Marking inspection

- Adjustable conveyor for various models

- Multi-position and orientation marking

- User friendly software under Windows XP